Product details

Descrition of Plastic extruder/test

plastic twine machine is for making raffia yarn, pp film yarn, pp split film yarn, pp tape yarn type baler twine rope. The line is designed and manufactured by introducing and absorbing foreign advanced techniques,and by improving domestic equipment inadequacies-It is suitable for forming,and rolling various flat yarn of thermoplastic plastics,such as the polypropylene,high density polyethylene and linear low density polyethylene,etc.plastic twine machine is for making raffia yarn, pp film yarn, pp split film yarn, pp tape yarn type baler twine rope. The line is designed and manufactured by introducing and absorbing foreign advanced techniques,and by improving domestic equipment inadequacies-It is suitable for forming,and rolling various flat yarn of thermoplastic plastics,such as the polypropylene,high density polyethylene and linear low density polyethylene,etc.plastic twine machine is for making raffia yarn, pp film yarn, pp split film yarn, pp tape yarn type baler twine rope. The line is designed and manufactured by introducing and absorbing foreign advanced techniques,and by improving domestic equipment inadequacies-It is suitable for forming,and rolling various flat yarn of thermoplastic plastics,such as the polypropylene,high density polyethylene and linear low density polyethylene,etc.plastic twine machine is for making raffia yarn, pp film yarn, pp split film yarn, pp tape yarn type baler twine rope. The line is designed and manufactured by introducing and absorbing foreign advanced techniques,and by improving domestic equipment inadequacies-It is suitable for forming,and rolling various flat yarn of thermoplastic plastics,such as the polypropylene,high density polyethylene and linear low density polyethylene,etc.plastic twine machine is for making raffia yarn, pp film yarn, pp split film yarn, pp tape yarn type baler twine rope. The line is designed and manufactured by introducing and absorbing foreign advanced techniques,and by improving domestic equipment inadequacies-It is suitable for forming,and rolling various flat yarn of thermoplastic plastics,such as the polypropylene,high density polyethylene and linear low density polyethylene,etc.plastic twine machine is for making raffia yarn, pp film yarn, pp split film yarn, pp tape yarn type baler twine rope. The line is designed and manufactured by introducing and absorbing foreign advanced techniques,and by improving domestic equipment inadequacies-It is suitable for forming,and rolling various flat yarn of thermoplastic plastics,such as the polypropylene,high density polyethylene and linear low density polyethylene,etc.

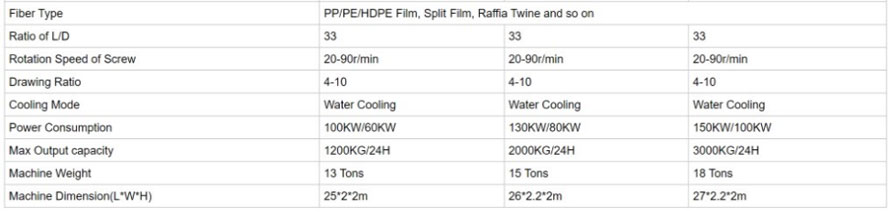

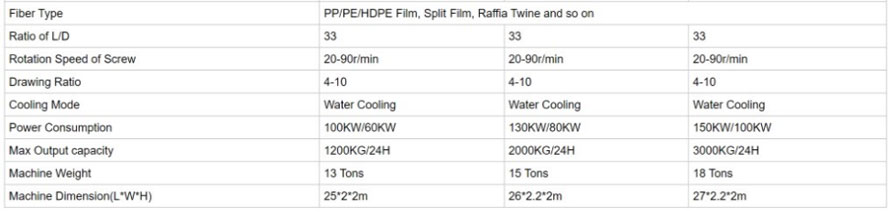

Technical paramters of Plastic extruder

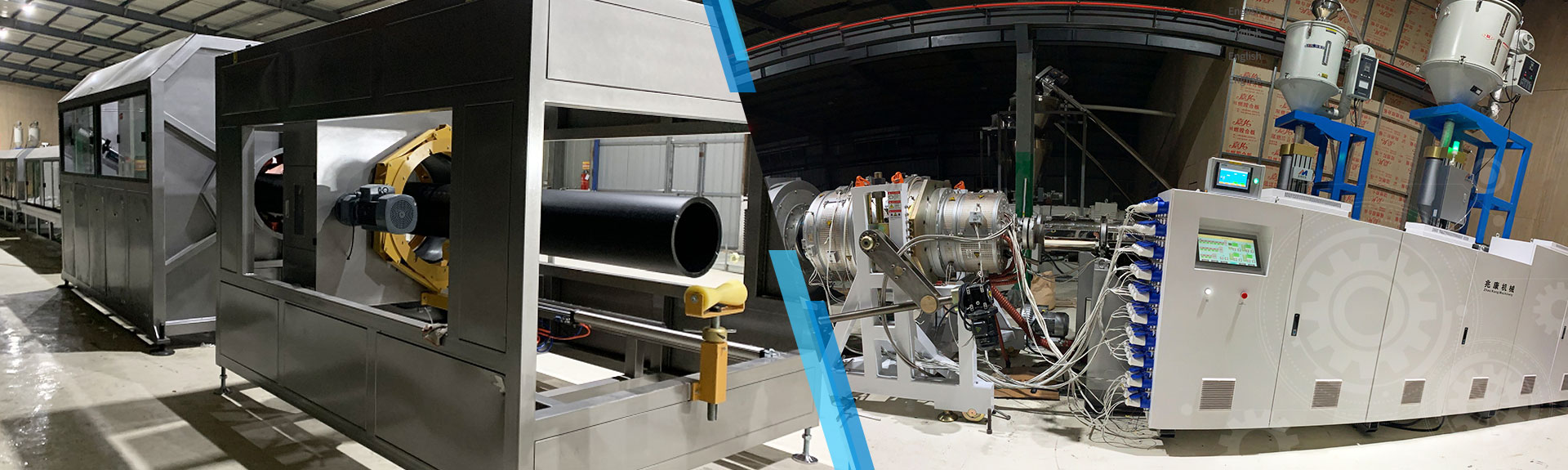

More photos of Plastic extruder

Company Profile

Factory show

About Us

Zhangjiagang Zhaokang Machinery Co., Ltd. is a professional supplier of plastic extruder equipment integrating R&D, manufacturing and sales. It has first-class design capabilities and advanced manufacturing levels. The company is located in Zhangjiagang City, Jiangsu Province, China.

With its excellent quality, high cost performance and high-quality after-sales service, the products sell well all over China, and are exported to Europe, America, Southeast Asia and other countries and regions.

Over the years, in order to meet the needs of the market and customers, the company has successively launched PE PVC PP PPR PEX PERT pipe extrusion production lines, profile extrusion production lines, sheet extrusion production lines, plate extrusion production lines, plastic recycling equipment and auxiliary equipment related to plastic processing.

After years of experience accumulation and continuous improvement, our equipment is energy-saving, efficient, stable in operation and low in failure rate.

Adhering to the tenet of "quality first, customer first", we will continue to improve our products and services, and continue to create value for customers. Welcome new and old customers to visit our company.

Our honor

Why choose us

Why choose us

Quality Experience Service in the field of plastic extruder

100 million

In China, we serve more than 20 plastic pipe production factories with an output value of over 100 million

100 production lines

Professional design engineers and commissioning engineers, both have educational backgrounds in machinery factories, have designed and debugged more than 100 production lines

7*24 hours

Professional sales and after-sales service team, proficient in English, Spanish, Russian and other languages, providing 7*24 hours online service

Shipment

Packed in woodenbox o FCL packed with plastic film.

Payment

We accept TT,LC etc,even BTC USDT etc crypto

FAQ

Q

Are you a factory or a trading company?

A

We have factories(Diben,Tongji,Zhaokang,Lanjing) and trade company(Saisaer),Diben focus on the research and development and manufacture of injection molding machines,Tongji focus on blowing molding machine,zhaokang focus on extrusion machine,Lanjing focus on package machine. saisaer committed to selling products of our sub-factories

Q

Where your factory?How can I get there?

A

Our factories are located in Zhangjiagang City (Zhaokang, Tongji), Ningbo City (Diben), Ruian City (Lanjing), these cities have high-speed rail, and we can also pick you up at nearby airports (Shanghai, Wenzhou, Wuxi).

Q

What's your main market?

A

We not only sell our machines in China, we also sell our machines to more than 30 countries and regions in the world.

Q

How are your factories doing in quaity control?

A

We adopt CAD to design our machine , which is highly standardized and modularized to ensure the machine's production precision and delivery speed,make maintenance easier. At the same time, all parts are made of well-known brands.

Q

How about after sale service?

A

We are available for our customers whole day and night, the first time to respond to our clients.

For each of our machines, we will do our best to do every after-sales service in its life cycle.

Service methods include on-site service or through modern means of communication such as Whatsapp,wechat etc.

Send Us Mail

Please message and we will get back to you!